Fiber-reinforced composites are used in modern structures such as wind turbines. But they have a crucial weak point. They dissolve inexorably over time. A team of researchers now seems to have found a suitable solution to this problem. The composite materials now developed are said to be able to repair themselves, significantly extending the service life of wind turbines and the like.

Composite material with self-healing powers

It may sound like magic, but it could revolutionize the field of industrial buildings. A team of researchers from Israel and the USA would like to have eliminated the crucial Achilles’ heel of composite materials with fiber reinforcement. In order to understand what this has been up to now, it is necessary to take a closer look at the structure of the material. Wind turbines and other structures use fibers made from sensitive raw materials such as carbon fibers or glass.

- Also interesting: Swiss develop environmentally friendly battery made of paper

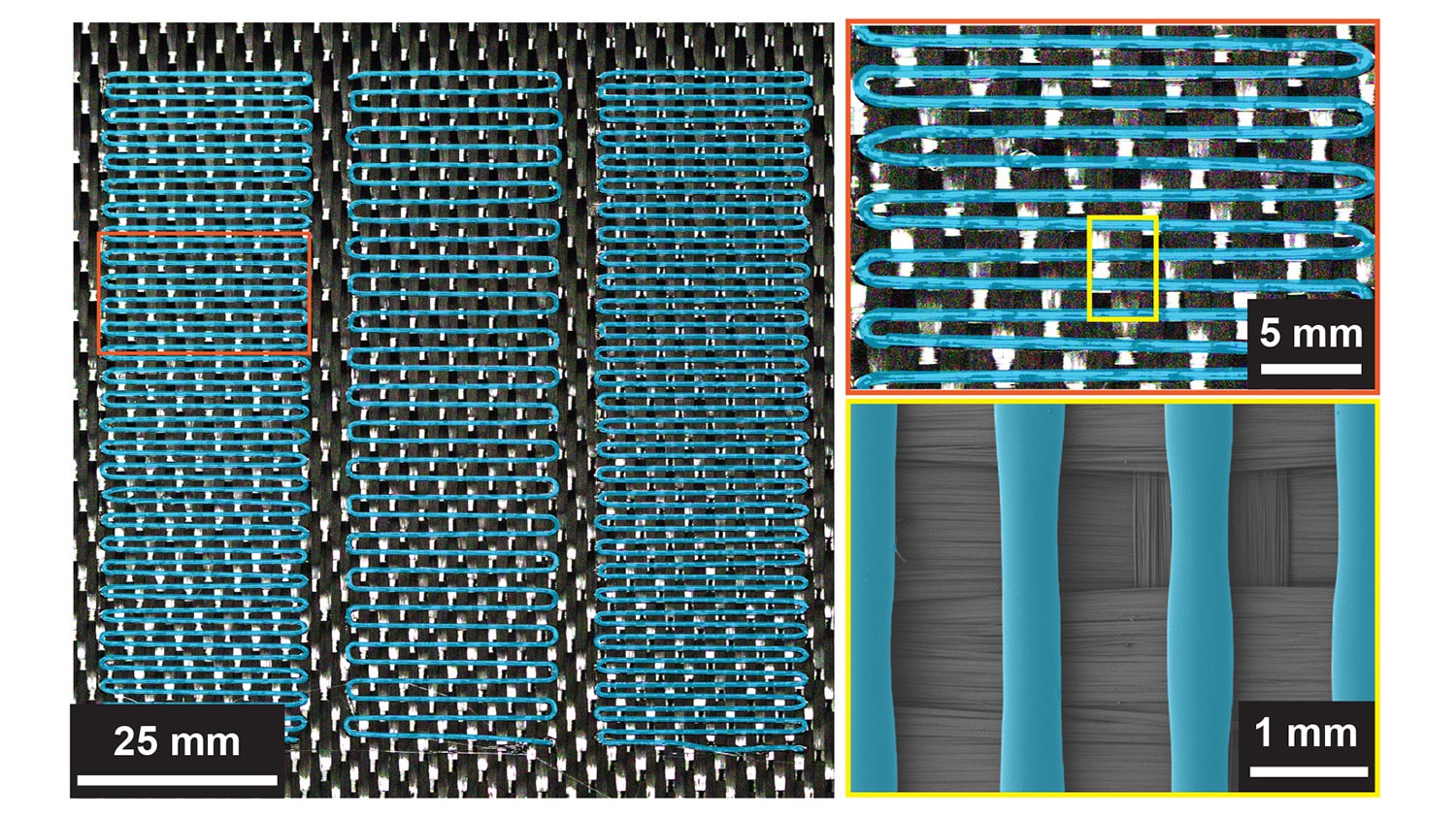

To protect them, they laminate them with a resistant plastic. However, this peels off over time, which makes the sensitive materials vulnerable again. In order to close any cracks in the plastic as quickly as possible in the future, thermoplastic healing agent is to be used. The research team printed this onto the fiber mat. In combination with heating elements that can heat up the fiber mats and activate the healing agent, the construct should then be able to heal itself.

- Also interesting: Enerkite aims to revolutionize wind turbines with flying kites

Cost-effective solution to problem

According to the researchers from North Carolina State University in Raleigh, University of Houston as well as the Israel Institute of Technology in Haifa, a major advantage should be that a repair could be carried out during operation. This would be particularly important for structures such as wind turbines, since they could continue to produce electricity during the repair. Furthermore, the researchers emphasize that the raw materials needed for the healing agent and the heating layers are not only cheap but also readily available. On top of that, this solution should be sustainable.

After all, one healing layer should be able to heal at least 100 cracks. That’s what one of the researchers responsible said as part of the scientific paper published in Nature. In this way, it should also be possible to amortize the few additional costs incurred in the production of the modern composites with self-healing. In addition, the heating layers could probably be conveniently used for de-icing. These two factors make the fiber-reinforced composites with self-healing properties interesting for many different areas of application.