The way shoes are designed, produced and worn is on the verge of radical change. With Vivobiome, Vivobarefoot presents a visionary platform that transcends industrial one-size-fits-all and puts the human foot at the center. Based on 3D scanning, AI-supported design and local manufacturing, Vivobiome promises nothing less than a new operating system for the footwear industry – individual, sustainable and digital.

- 3D scanning replaces standard sizes: Each shoe is based on a precise foot scan and is fitted to the millimeter.

- 3D printing instead of an assembly line: production is local, waste-free and needs-based thanks to selective laser sintering.

- First prototype: Tabi Gen 01: a sandal inspired by traditional foot freedom and state-of-the-art technology.

- Digital ecosystem: AI, biomechanical data and medical research flow into an adaptive system for natural movement.

Tailor-made instead of standardized: A radical new beginning

The shoe market is still dominated by one-size-fits-all shoes – even though hardly any two feet are the same. This is exactly where Vivobiome comes in. Instead of mass-produced goods, the platform delivers custom-made shoes based on a digital 3D scan. In just a few seconds, the foot is completely measured, including shape, posture and pressure distribution. This data serves as the basis for the design, which is then individually manufactured using a 3D printing process.

The first harbinger of this new philosophy is the Tabi Gen 01, a sandal that sets new standards not only ergonomically but also functionally. It allows independent movement of the big toe – a key element for stability and natural foot development. The combination of a precise fit, flexible materials and a barefoot-like feel stimulates the foot muscles and combats typical problems such as poor posture or limited mobility.

Sustainability meets precision: the digital micro-factory

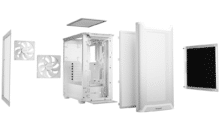

With the development of Vivobiome, Vivobarefoot goes far beyond pure shoe design. Production takes place in so-called micro-factories – decentralized, locally anchored units that conserve resources and produce without waste. The materials used are either bio-based, recyclable or designed to be durable in order to exist in a closed cycle.

The technology in the background is also impressive: Unreal Engine 5, originally developed for video games, is used here as a design platform. An AI continuously evaluates new user data, adapts designs and optimizes production. This makes each new generation of shoes smarter, more adaptable and more sustainable. Parallel to the product launch, the Vivobiome Health Lab is opening in London, where researchers from the fields of medicine, exercise therapy and materials science are working together on the future of foot health.

The first step into a new era

The Tabi Gen 01 marks the starting point of a long-term change. The first production run is limited to 590 pairs and is only available via a foot scan in London or Prague. Vivobarefoot operates its own pop-ups there, where interested parties can create their scan and thus become part of the movement. For everyone else, it is possible to be digitally measured now – and secure a place for future generations.

In the future, further micro-factories will be set up around the world, including in Germany, Austria and Switzerland. The aim is a globally networked but locally producing system. It combines the advantages of state-of-the-art technology with regional production – and creates a new form of shoe: individual, regenerative and functional.

Conclusion

With Vivobiome, Vivobarefoot is not just delivering an innovative shoe, but a holistic system that is rethinking the footwear industry. The Tabi Gen 01 is the first visible step – available for around 250 euros only after a personal scan. Anyone who misses the launch can still make a reservation. Because one thing is clear: the future of the shoe doesn’t start in the warehouse – it starts with the foot. Further details can be found on the official website.