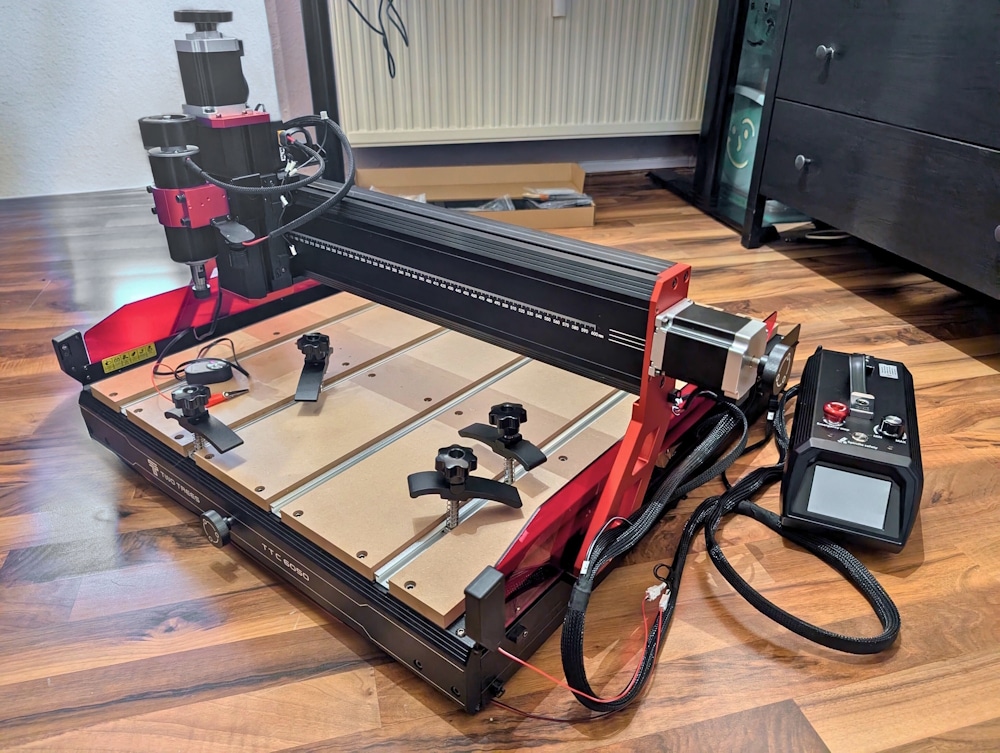

With its generous 600×500mm working area and a 500W spindle, the TwoTrees TTC-6050 aims to make entry-level CNC milling affordable. As the successor to the popular TTC-450, it promises greater precision, higher speed and more professional features. With an RRP of €1,745, the desktop CNC router is clearly positioned in the high-end hobby segment. We took a closer look at the device and put the TwoTrees TTC-6050 to the test to see whether it justifies the significant premium price compared to smaller models.

TwoTrees TTC-6050: The technical data at a glance

| Category | Specification |

| Working area | 600 × 500 × 100 mm |

| Spindle | 500W, 12,000 rpm (800W optional) |

| Feed rate | Up to 5,300 mm/min |

| Precision | 0.05 mm positioning accuracy |

| Drive | Nema 57 motors, C7 ball screws |

| Guides | Linear plain bearings on all axes |

| Control unit | 3.5″ touchscreen, separate control unit |

| Connectivity | WiFi, USB, microSD card |

| Software | GRBL, Artcam, Fusion360, Carveco Maker |

| Safety and security | Infrared sensors, emergency stop switch |

| Collet | ER11 (0.5-7mm shaft diameter) |

| materials | Wood, MDF, acrylic, aluminum, copper, stainless steel |

| Dimensions | 900 × 700 × 400 mm (assembled) |

| weight | approx. 39 kg |

| The price | RRP 1.745 € |

40 kilo machine in a box

The TTC-6050 comes complete in a single, but very heavy box weighing around 40 kilograms. As soon as it is lifted, it becomes clear that this is a machine to be taken seriously. The first glance inside the box reveals an impressive amount of components, which are nevertheless neatly packed.

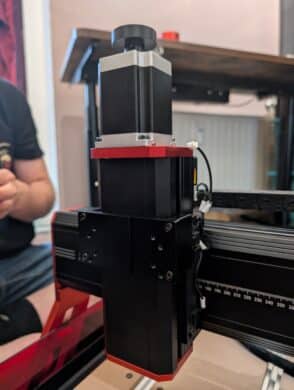

Several solid aluminum profiles form the basic frame, along with the linear guides for all three axes, the ball screws and, of course, the 500W spindle with its robust holder system. The separate control unit with the 3.5″ display makes a professional impression as soon as it is unpacked and gives an idea that there is more than just toys waiting here.

The organization of the small parts is particularly positive. All screws, nuts and fasteners are packed in labeled bags. Each screw is clearly labeled and can be found in the illustrated manual. This saves hours of searching and puzzling, as is often the case with other kits.

2.5 hours of screwing fun with pitfalls

Assembling the Twotrees TTC-6050 for our test took time and patience. We needed a good 2.5 hours of pure assembly time, plus time to study the instructions and make minor adjustments. Anyone who has assembled a smaller CNC router before will find their way around more quickly, but it can be tricky in some places. The instructions guide you logically through the assembly, starting with the base frame. All aluminum profiles are precisely milled and fit together with millimeter precision. The connections are made using robust screw connections, which should remain stable even after prolonged use.

Particular attention should be paid to the positioning of the side parts. Several components are designed specifically for the left or right and can be mounted incorrectly, but will then not function properly. The instructions indicate this with red warnings, but you should still take a close look.

All screws should initially only be hand-tightened so that the entire system can still warp. Only when all parts are in position are the connections tightened to the appropriate torque. If you tighten them too early, you will have problems with precision later on.

The enclosed small screwdriver for the small screws seems fragile – we were constantly worried that it would break. Using our own tools made assembly much easier.

When the Z-axis goes its own way

On our test device, we had a small problem with the central Z-axis, which initially had noticeable play. The first test cuts showed slight inaccuracies and vibration marks on the side walls. A check showed that one of the central connecting screws was not properly tightened. After retightening, all problems disappeared immediately. The cuts were precise and the surfaces smooth. This shows how important careful assembly is, but also that such problems can usually be rectified quickly.

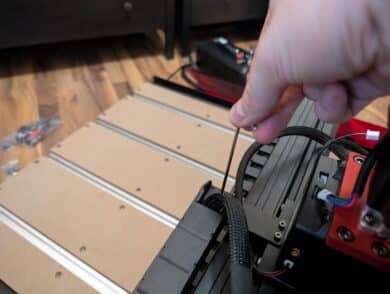

The communication cable between the spindle and the control unit deserves a special mention. The plug looks practically identical on both sides, but only fits in one orientation. The instructions clearly mark “Side Up” on the plug – if you ignore this, the spindle will not work. The same applies to the connection to the control unit. These small details can be frustrating, but are quickly solved if you follow the instructions exactly.

Touchscreen meets analog handwheels

The separate control unit makes an excellent first impression. The 3.5″ touch display is sharp and responds precisely to inputs. The menu navigation is logically structured and easy to understand, even for CNC newcomers. All important functions can be accessed via a few menu levels.

The touch display is brilliant for fine positioning in the mm range – but rather slow for large travel distances. This is where the three manual handwheels on the machine come into play. One each for the X, Y and Z axes enables rapid positioning over longer distances, but can also be used for fine adjustments.

The Z-axis measuring tool supplied proves its worth in practice: the spindle moves down automatically, taps the tool and then knows exactly where the workpiece surface is located. This makes height adjustment much more precise than manual measurement.

Infrared sensors as digital bodyguards – testing the TwoTrees TTC-6050

A cool highlight of the TTC-6050 are the integrated infrared sensors for danger detection – but they can also be quite annoying at the same time. The principle is simple: sensors monitor the work area like a safety barrier on an elevator. If the light beam is interrupted, the spindle stops within fractions of a second.

We quickly noticed this when we wanted to vacuum away the chips while working with the vacuum cleaner – as soon as you break through the light barrier, the machine stops immediately. This can be frustrating during longer milling jobs. After a safety stop, however, processing continues smoothly – without any loss of position or other problems.

Bottom line: An ingenious safety function that you don’t tend to find in this price range. However, you should get used to the fact that any movement in the working area leads to a stop – which is actually the intention.

500 watt spindle: Solid for wood and plastic

The 500 W spindle supplied does a good job for normal hobby projects. At 12,000 rpm, it has enough power for clean cuts in wood and softer materials. It runs much more quietly than the usual hand routers and doesn’t get really hot, even when used for long periods. After one hour of continuous operation, it was only warm to the touch – the air cooling is completely sufficient.

The ER11 collet system is familiar from many CNC routers and accepts tools from 0.5 to 7 mm. The collets supplied are well made and hold the cutters securely in place. TwoTrees includes a few small cutters, mainly thin 1/8″ parts. If you want to do serious work, you should buy a 1/4″ collet – thicker cutters are more stable and vibrate less. The ER11 collets can be bought anywhere for a few euros.

For those who need more power: TwoTrees offers an optional 800W spindle with 30,000 rpm for around 80 dollars – then even harder material is possible.

SD card beats permanent cable

The TTC-6050 works with standard GRBL firmware, which guarantees maximum compatibility with common CAM software. Artcam, Fusion360, Carveco Maker or even free solutions work without any problems. Support for the iCarve format, which is popular with many hobby users, is particularly practical. The supplied Candle program offers solid basic functions for direct operation. The user interface is somewhat spartan, but all the necessary features are available.

A real plus point is the option of standalone operation. G-code is copied to a microSD card and can be executed directly from the machine. This eliminates the need for a permanently connected computer and makes the machine much more flexible to use. No occupied workstation, no cable problems, no software crashes during long milling jobs. File management via the touch display is functional, even if long file names are truncated. WiFi functionality is available, but the stability of the connection was not always optimal. For serious work, transfer via SD card is recommended.

First cuts in plywood and pine – our TwoTrees TTC-6050 test shows what’s possible

For the first tests, we carried out various projects of varying complexity. From simple engraving to precise fits, everything was included. The results are impressive and the TwoTrees TTC-6050 shows a lot of power. The first cuts in plywood and pine wood immediately revealed the quality of the machine. Clean edges with only minimal reworking – a little sandpaper was necessary, but this could have been due to the material or our settings.

The TTC-6050 also works cleanly on more complex geometries with many changes of direction. Corners are cut precisely, curves are smooth without jerking or stuttering. A test with filigree lettering also showed good results. Even small details are worked out cleanly, and the 500W spindle definitely has enough power for these materials.

From MDF to aluminum

In addition to plywood and pine, we put the TTC-6050 to the test with a wide variety of other materials. As expected, MDF works perfectly – clean cuts without tear-outs, even with complicated geometries. The 500W spindle has enough power for fast processing with good surface quality. With multi-layer plywood panels, you should be a little more careful, as the different layers of glue can be of varying hardness and lead to uneven feed.

The TTC-6050 cuts acrylic very cleanly, although moderate speeds are important to prevent the material from melting. Excessively high speeds or blunt cutters quickly lead to unsightly melting edges. POM and other engineering plastics also work well. Light aluminum machining is possible with the right milling cutters and adjusted parameters. Sharp tools and moderate speeds are important. The 500W spindle reaches its limits here, but still manages thin sheets or simple geometries. To be honest, we had to dispose of a few workpieces during the learning phase – incorrect speeds, unsuitable milling cutters or overly aggressive parameters quickly led to unusable results.

T-slots against chaos – how the clamping system performs in the TwoTrees TTC-6050 test

The T-slot clamping is a significant improvement over MDF panels with threaded inserts, which are common on smaller models. The material can be fixed securely and flexibly. The combination of aluminum T-slots and MDF strips is practically well thought out. The MDF areas are used for normal work, where through routing is no problem. The T-slots are available for precise clamping. However, the clamping accessories are somewhat limited.

Only a few clamping claws and screws are included in the scope of delivery. Additional T-slot accessories should be purchased for serious work. The standard clamping is only sufficient for simple clamping. We had to learn this painfully when an inadequately clamped workpiece became independent when testing higher speeds. Fortunately, the infrared sensors reacted immediately and stopped the spindle. The solid basic construction of the worktop is evident. The aluminum T-slots are precisely milled and the MDF strips are inserted flat. Even after several weeks of intensive use, there are no signs of wear or deformation.

Maintenance and what else you should consider

The most important maintenance measures are limited to the essentials. The linear guides should be cleaned and re-greased occasionally. TwoTrees recommends a thorough cleaning every 100 operating hours. In practice, this is rarely necessary for normal hobby use. The T-slots must be regularly cleaned of chips, especially after processing wood or other fibrous materials.

The spindle and the Collet system are practically maintenance-free. Only with very intensive use or after processing metals should the collets be cleaned occasionally. After our test phase, however, there were no significant signs of wear. The aluminum construction makes a very durable impression. Wear parts such as milling cutters and collets are standard components and can be procured inexpensively. The stepper motors and the control electronics have proven to be reliable. There were no failures during the test period.

Quieter than expected – how the TwoTrees TTC-6050 sounds in the test

The TTC-6050 is surprisingly quiet for a machine of this size. The 500W spindle is significantly quieter than a conventional router and the stepper motors also work without any disturbing noises. During normal operation, the noise level is around 60-65 dB – the equivalent of a normal conversation. This is perfectly acceptable for hobby workshops, and there should be no problems with operation in residential areas. However, it can certainly get louder at higher speeds – especially with soft pine wood, the spindle then screeches properly and gets really loud.

With dimensions of 900×700×400 mm, the TTC-6050 takes up a lot of space on the workbench. There is also space for the operator and any material feed. A space of at least 120×100cm should be planned. The weight of around 45kg makes the machine stationary. Frequent repositioning is not practical. The integrated LED lighting is bright and even. Even when working in darker corners of the workshop, the illumination of the work area is sufficient.

Upgrades and accessories

TwoTrees offers various accessories for the TTC-6050. Of particular interest is the “Monster M1” vacuum cleaner system for €95, which is mounted directly on the 500W spindle and extracts chips and dust directly at the point of origin. As a powerful alternative, an 800W spindle with 30,000 rpm is available for around €80, which is also suitable for harder materials such as aluminum or stainless steel.

However, there is a catch: the vacuum cleaner system is not compatible with the 800W spindle. So you have to choose between more power or better chip extraction. The 800W spindle is significantly more powerful, but must be controlled manually via a separate control panel and cannot be controlled by software.

The Monster M1 system impresses with well thought-out features: 6000 Pa suction power thanks to a brushless motor with 50,000 rpm, automatic start/stop function and overheating protection. The 2.8 liter dust container is transparent and equipped with a zipper, which makes emptying easier. An additional LED ring on the suction connection improves illumination and an integrated negative ion generator is even said to purify the air. TwoTrees also offers laser modules for engraving work, which further extend the machine’s range of applications.

Competition and price comparison

At around €1,400, the TTC-6050 plays in the upper hobby league. There are various suppliers with similar concepts but different focuses. Compared to the smaller TTC-450, the 6050 offers 50% more work surface and 25% more Z-height. The more stable aluminum construction is reflected in better surface qualities and higher possible speeds. However, the price difference is considerable – the TTC-450 only costs around a third.

The most direct competitor is the Genmitsu PROVerXL 6050 Plus for around €1,700. It offers a similar working range (600×500×115mm), but is more expensive and less equipped. The 300W spindle is weaker than the 500W of the TTC-6050, the NEMA 23 motors have less torque than the NEMA 57 of the TwoTrees machine. On the other hand, Genmitsu has dispensed with the touchscreen interface and the innovative infrared sensors – features that clearly set the TTC-6050 apart from the competition.

Although the in-house TTC H40 for around €1,200 offers a larger working area, it is significantly less stable and only achieves a feed rate of 1,000 mm/min instead of 5,300 mm/min. It also lacks the safety sensors and the enclosed design. The price of the TTC-6050 is fair for the working range offered, the solid construction and the innovative safety features. The option of standalone operation is a real added value that is missing or costs extra with many competitor products.

Conclusion: Solid entry with real innovations

The TwoTrees TTC-6050 proves in the test that it manages the balancing act between hobby suitability and professional features convincingly. The generous 600×500mm working area offers space for serious projects, while the robust aluminum construction provides the necessary stability and precision. The absolute highlight is the innovative infrared safety sensors, which we have never seen before in this price range. They significantly increase work safety and give beginners in particular additional confidence.

Standalone operation via SD card makes the machine much more practical than computer-controlled alternatives. The processing quality is impressive across the board. The 500W spindle is sufficient for wood and soft materials, but reaches its limits with harder materials. Assembly is time-consuming and requires manual skill. The space requirement is considerable and makes the machine only interesting for appropriately equipped workshops. For the price, you get a CNC router that doesn’t have to hide behind significantly more expensive machines.

- Large 600×500mm working area

- Robust aluminum construction

- Innovative infrared safety sensors

- Standalone operation without computer

- Precise linear guides and ball screws

- Good software support (GRBL)

- T-slot clamping system

- Quiet operation

- Integrated LED lighting

- Fair price-performance ratio for the size

- 500W spindle limited for hard materials

- Assembly requires time and patience

- Takes up a lot of space in the workshop

- WiFi function still has room for improvement

- Small milling cutters included in the scope of delivery

- Clamping accessories in short supply

- High purchase price

- Not for occasional users